Keep your machiner

EQiblyNix

0

266

2024.12.18 11:03

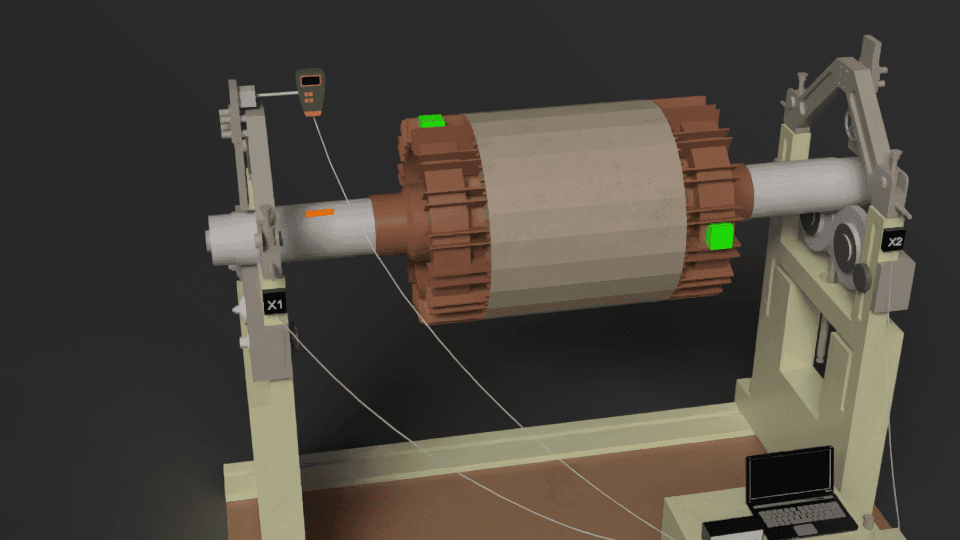

Detailed Rotor Balancing Process

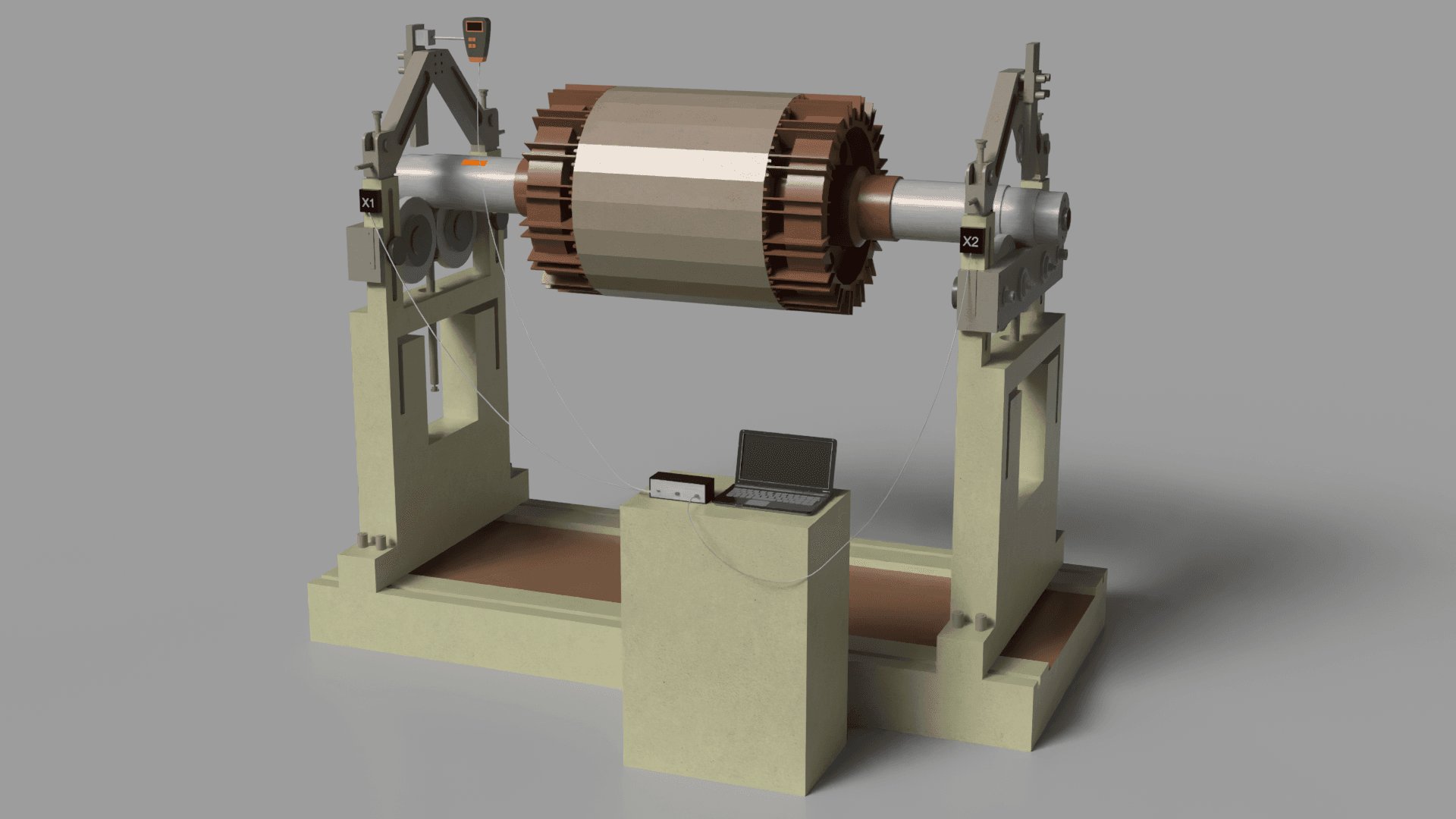

Getting the Equipment Ready

- Ensure the instrument is complete with all necessary components: vibration transducers, laser tachometer, magnetic stand, software, and other accessories.

- Establish a USB connection between the instrument and the computer, ensuring the software is set up properly.

Sensor Installation

- Mount the vibration transducers securely on the machine's housing where vibrations are most pronounced, typically near the bearings.

- Aim the optical rpm sensor at the rotating shaft and apply a reflective strip to the shaft for phase angle data acquisition.

Starting the Program

- Open the Balanset application on your PC.

- Configure the software for either single-plane or two-plane balancing, based on the rotor's characteristics and the desired outcome.

Initial Vibration Measurement

- Bring the rotor to its normal operating rotational frequency.

- The program will record the vibration amplitude, rpm, and phase, providing a baseline measurement of the existing imbalance.

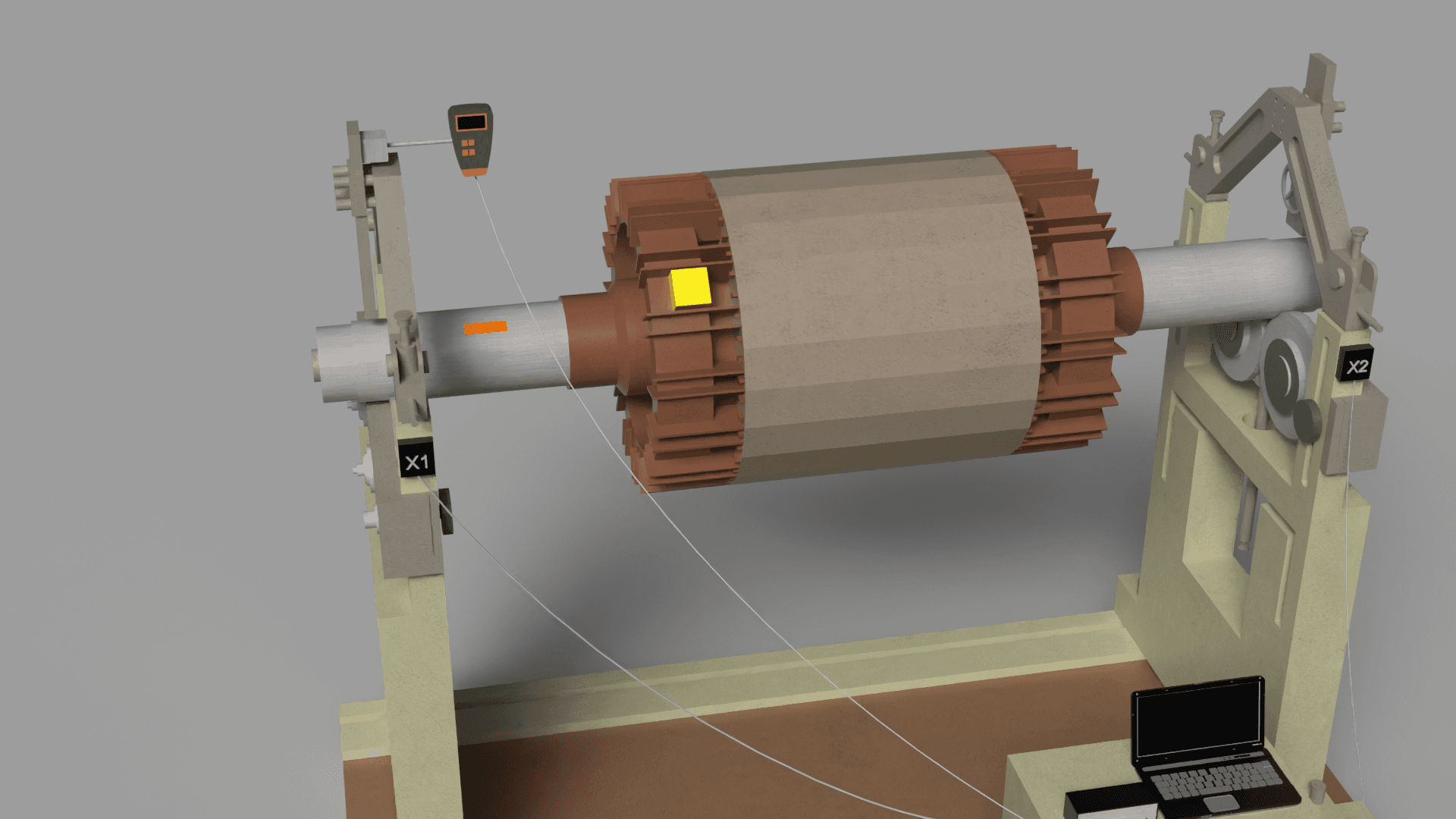

Attaching the Trial Weight

- Bring the rotor to a standstill and affix a trial weight at a predetermined point on the rotor, specifying its mass in the software (typically in grams).

- Run the rotor again, allowing the software to measure the effects of the trial weight on vibration and phase.

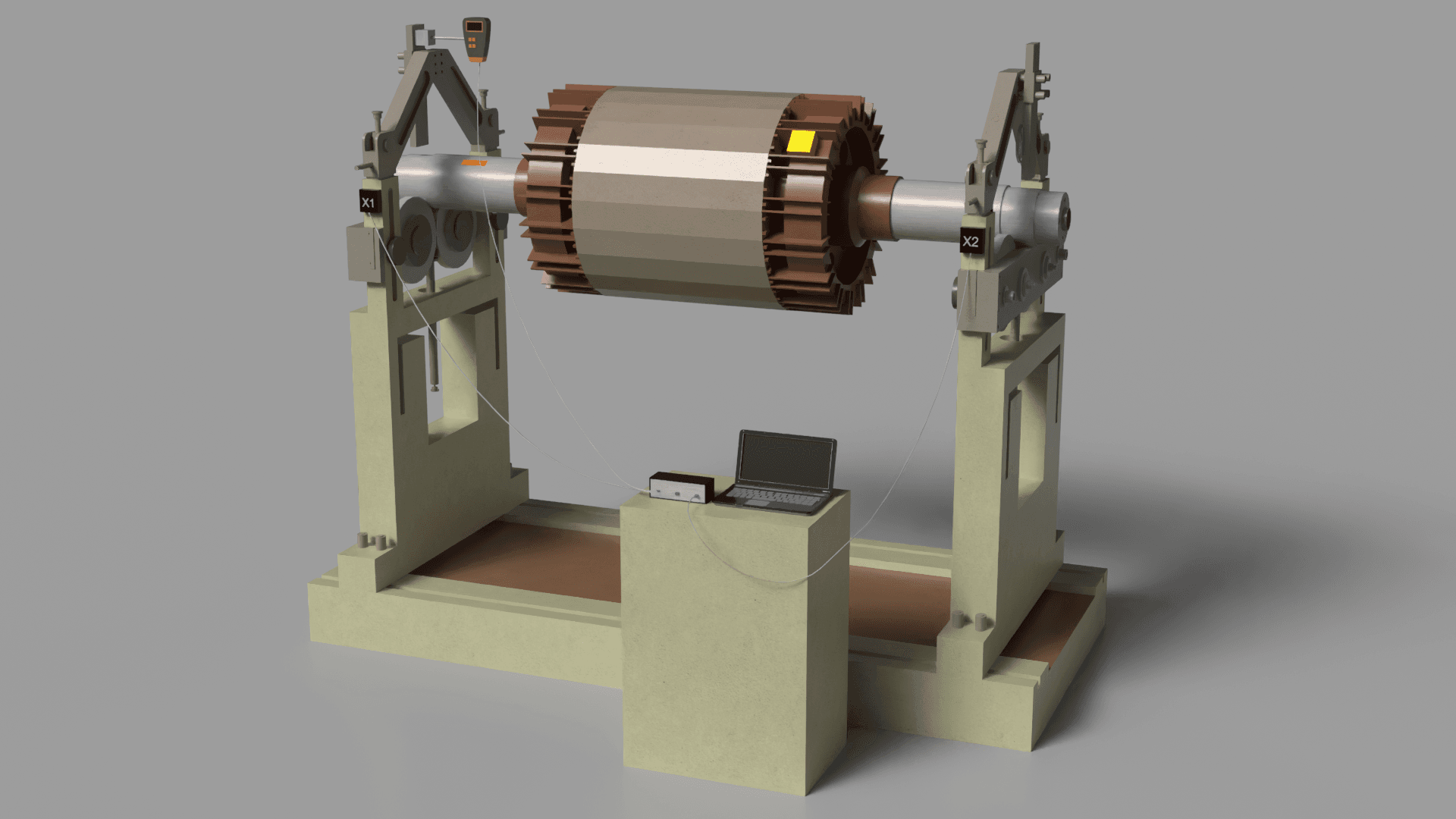

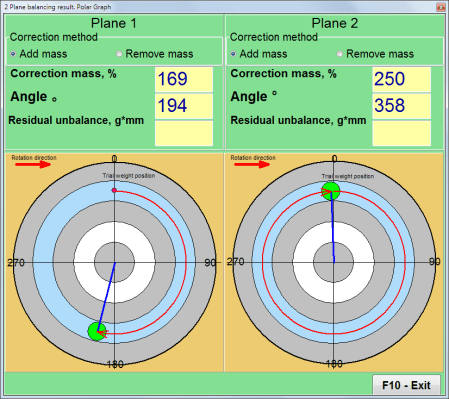

Calculating the Correction Weight

- The software uses the measured values to automatically compute the necessary compensating weight's magnitude and placement angle.

- The results of the calculation are shown both numerically and visually through charts and graphs.

Mounting the Compensating Weight

- Attach the computed compensating weight to the rotor as indicated by the software's output.

- If necessary, perform intermediate checks to verify that the imbalance is being reduced.

Final Check and Balance Confirmation

- After installing the correction weight, run the rotor again and check the residual vibration level.

- If the measured vibration falls within the tolerance defined by ISO 1940, the balancing process is considered successful.

- Should the vibration still be excessive, repeat the balancing steps, making further adjustments to the corrective weight as needed.

Generating a Documentation of the Balancing Results

- The program stores the balancing data, allowing you to generate and print a comprehensive report including vibration measurements, corrective weight details, and its angular placement.

Final Recommendations

- Verify the secure attachment of all balancing weights and measurement sensors.

- Check that the rotor's rotation is smooth and free from undue noise or vibration.

- If the rotor is part of a complex mechanism, verify the proper interaction of all its components.

Following this procedure enables accurate balancing, minimizes vibration, and prolongs the service life of the equipment.

Instagram: https://www.instagram.com/vibromera_ou/ Youtube : https://youtu.be/guA6XJ-ArZM?si=vmkuX7RILzKBl0zL Our website about Balancing report Machinio: https://www.machinio.com/listings/98380186-portable-balancer-vibration-analyzer-balanset-1a-full-kit-in-portugal Facebook: https://www.facebook.com/marketplace/item/350151228150722